What is Our Technology?

Through a proprietary chemical process that molecularly binds with cellulose fibers, we have been able to “lock the fibers,” so they are no longer susceptible to moisture.

What Is Promising About Our Technology?

By preventing absorption, the material no longer weakens or swells when exposed to water, maintaining its structural integrity and strength.

And along with this resistance to water absorption, our process alters natural fibers in such a manner as to allow air to pass through the material, making the material breathable, further removing the threat of water damage.

Through chemical and molecular innovations, we are developing new cellulosic fiber-based products that will allow for reduced consumption, while increasing reusability, as well as recyclability – all of this at a fraction of the cost of traditional products.

This new approach will allow us to be better stewards of our environment, while reducing cost and strain on our natural resources.

Biodegradable

Less harm to our environment No emissions from toxins Less waste going into environment Sustainable business model

Recyclable

Able to reuse and reduce waste

Repulpable

Reduce waste by reusing materials in upcycled products again and again

Fire-resistant

Safer products with less risk of loss and damage

Insect/Mildew/Mold Resistant

Products withstand the elements of nature with less loss and damage

Hydrophobicity

Materials withstand water and rain exposure with little damage and loss and maintain strength and structural integrity

Time To Work Smarter To Save Our Environment

Time For A New Approach

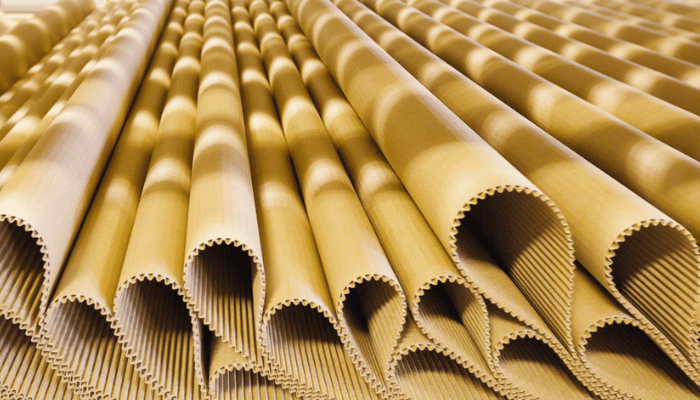

A Primer About Cellulose Technology

Cellulose is an organic compound and the most abundant biopolymer on Earth. It is an important structural component of green plants used in manufacturing paper and cardboard products. Around 90% of shipped products in the US are packaged in cardboard.

Virgin pulp is made only by using cellulose, meaning it does not contain any recycled content and is made directly of the pulp of trees or cotton. Papers and tissue papers that are produced with virgin pulp is categorized as high-quality products.

The properties of cellulose make it attractive as a substitute for plastics. However, the challenge with cellulose is its water content and absorption, which can contribute to its degradation leading to poor mechanical properties and reduced product life.

What is needed is a way to strengthen the cellulose at the molecular level, which historically has been a complex phenomenon.

Traditional Cardboard Products vs. BEST’s Treated Cellulose Technology

Our Treated Cellulose Solution

Possible Applications

Paper and pallet manufacturing and reuse

Construction material that is fire retardant and lighter yet maintains significant strength

Education and Science

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Education and Science

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Education and Science

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.