BEST Solutions for Retail Transportation Pallets

With roughly 2 billion pallets circulating in the United States, global retailers want to reduce their carbon footprint through sustainable and eco-friendly operations. Since these retailers carry vast inventories and depend on complex supply chain operations, they want sustainable solutions to transport goods. One efficient, cost-effective option? Recycled cardboard pallets for retail transportation.

Cardboard as a material is state-of-the-art and currently the preferred choice for pallets over wood.

However …

cardboard has significant liabilities as well.

Vulnerable to Moisture

When compared to wooden pallets, cardboard can neither sustain nor resist moisture for long periods of time so they can’t be stored outside. This makes them highly susceptible to water and humidity during transportation, which can severely weaken their structure.

Not as Reliable as Wooden Pallets

While the main advantage of cardboard is its low cost and lightweight nature, they are not particularly sturdy or reliable in comparison to wooden pallets. Cardboard pallets have a tendency to buckle or collapse under the weight of heavy cargo, which can lead to disastrous consequences—losses of both money and reputation for the retailer.

Not Particularly Hygienic

This can cause issues for a supply chain that deals with perishable and consumable products. While wooden pallets are sanitized regularly, this is not a viable option for cardboard pallets due to their absorbent nature. This can result in product contamination during transportation, leading to costly recalls and negative publicity for the retailer.

Vulnerable to Legal Issues

Using flimsy and unreliable pallets can result in safety incidents, workplace injuries, or even fatalities, leading to lawsuits and legal proceedings against the retailer.

The BEST Solution

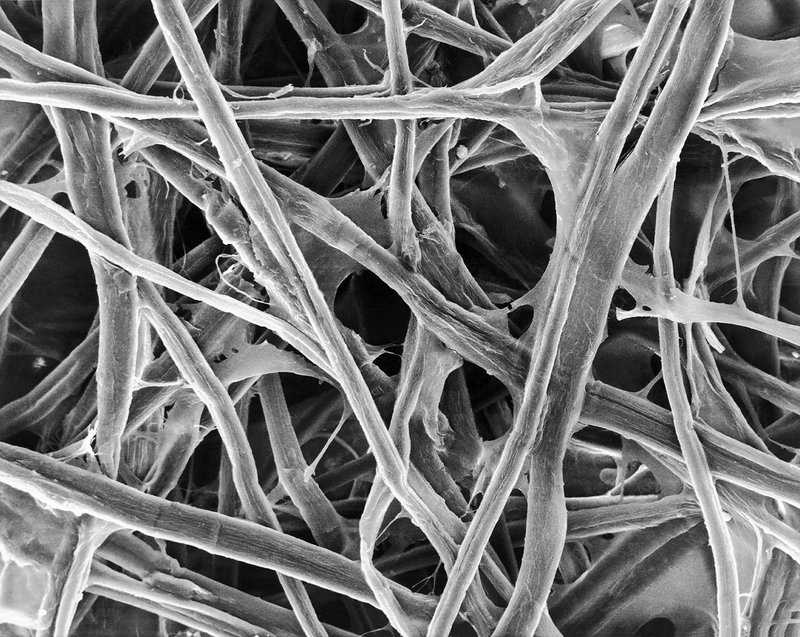

Through a proprietary chemical process that molecularly binds with cellulose fibers, BEST can “lock the fibers,” making them resistant to moisture. By preventing absorption, the material no longer weakens when exposed to moisture, and can maintain structural integrity and strength.

Along with this resistance, BEST’s process alters natural fibers in such a manner as to allow air to pass through the material, making material breathable and further removing threats of moisture damage.

BEST is developing new cellulosic fiber-based products that allow for reduced consumption, while increasing strength, reusability and recyclability—at a fraction of the cost of traditional products.